The electronics industry is constantly evolving, and companies need reliable and efficient printed circuit board (PCB) services to stay competitive. PCBway is a leading provider of PCB solutions and services that help companies innovate and grow. In this blog, we will explore PCBway's role in the electronics industry and the various services they offer.

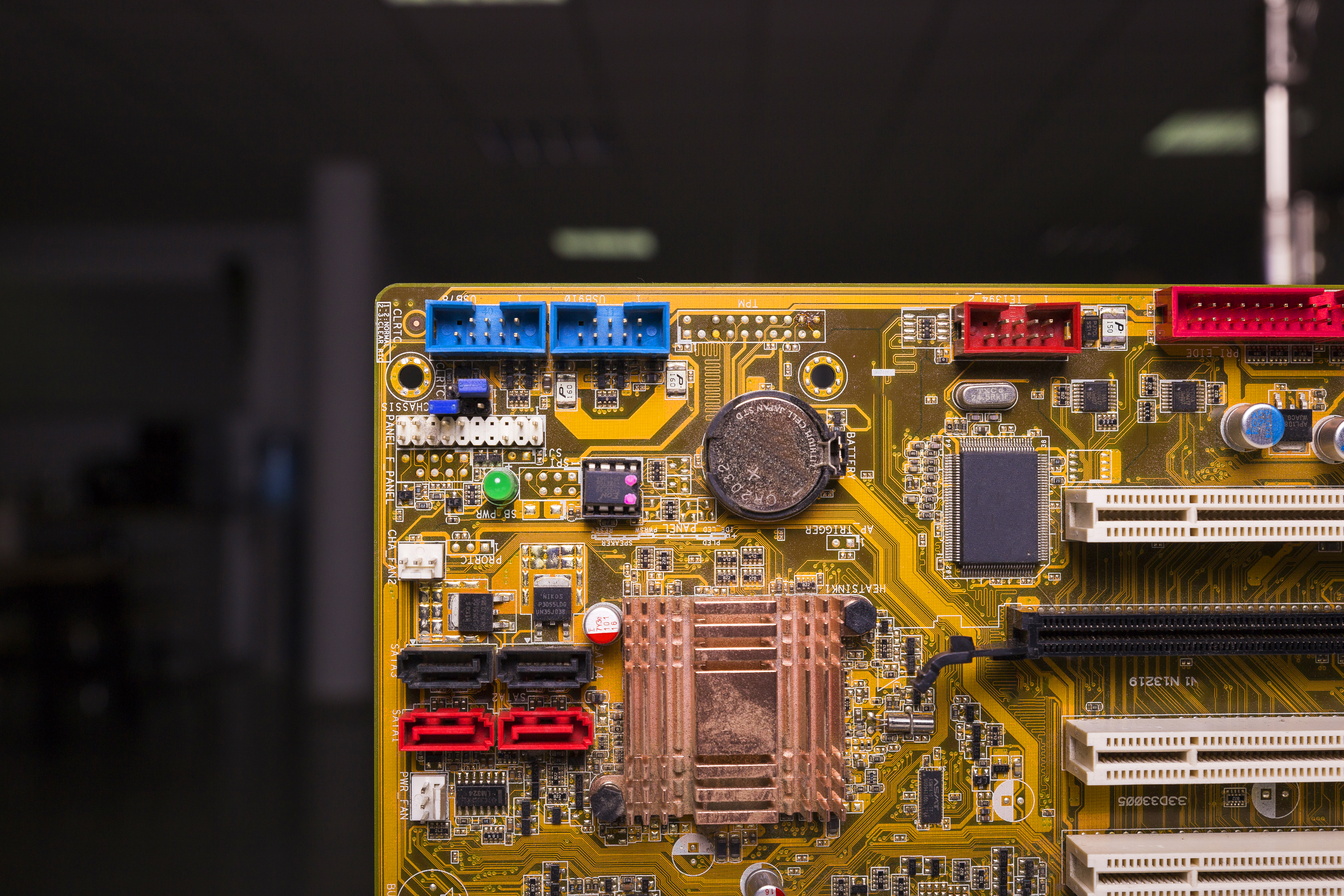

PCBway's core services include PCB prototyping, PCB fabrication, PCB assembly, and PCB stenciling. Let's take a closer look at each of these services.

PCBway's Capabilities

PCBway offers a wide range of PCB capabilities to fit all of your PCB needs. They have a state-of-the-art PCB manufacturing facility that is equipped with the latest technology and equipment. Their capabilities include:

- PCB Prototyping: PCBway can help you quickly prototype your PCB design with its fast turnaround times and affordable pricing.

- PCB Manufacturing: They offer a wide range of PCB manufacturing services, including single-sided, double-sided, and multi-layered PCBs.

- PCB Assembly: PCBway provides a full range of PCB assembly services, including surface mount technology (SMT), through-hole assembly, and mixed technology assembly.

- PCB Design: Their team of experienced designers can help you create a custom PCB design that meets your specific requirements.

- PCB Testing and Inspection: PCBway ensures the quality of their PCBs with rigorous testing and inspection procedures.

- PCB Stencils: They offer high-quality PCB stencils that can help you achieve precise and accurate solder paste application.

- PCB Components: PCBway provides a wide range of components, including resistors, capacitors, and ICs, to meet your PCB assembly needs.

- PCB Accessories: They offer various accessories, such as PCB connectors, wires, and cables, to ensure a seamless PCB assembly process.

With such a comprehensive range of capabilities, PCBway can meet the needs of a wide range of industries, including aerospace, automotive, consumer electronics, telecommunications, and medical.

Supporting Innovation and Growth

PCBway plays a vital role in supporting innovation and growth in the electronics industry. They understand that innovation is key to staying competitive, and their services help companies bring their ideas to life. PCBway's capabilities and expertise enable them to offer customized PCB solutions that meet their customers' unique needs.

Furthermore, their fast turnaround times and affordable pricing allow companies to quickly iterate their designs and prototypes, enabling them to bring products to market faster. This efficiency can significantly reduce product development costs and help companies stay ahead of their competition.

PCBway is also committed to providing exceptional customer service. They have a team of experienced engineers and designers who work closely with their customers to ensure that they get the best possible PCB solutions. Additionally, their customer support team is available 24/7 to answer any questions or concerns that customers may have.

Sustainability

PCBway is also committed to sustainability and reducing the environmental impact of its operations. They use eco-friendly materials and production processes to minimize waste and reduce their carbon footprint. Furthermore, they have implemented a comprehensive recycling program that ensures that all waste is responsibly disposed of or reused.

PCBway's dedication to sustainability and social responsibility is a testament to its commitment to making a positive impact on the environment and communities.

Quality Assurance

One of PCBway's top priorities is ensuring the quality of its products and services. They have implemented a rigorous quality control system that includes testing and inspection at every stage of the production process. This system ensures that their PCBs meet the highest quality standards and are free from defects.

PCBway's quality assurance process includes:

- Incoming Material Inspection: All incoming materials are thoroughly inspected to ensure they meet PCBway's strict quality standards.

- In-Process Inspection: PCBway conducts in-process inspections to ensure that each stage of the production process meets its quality requirements.

- Final Inspection: All finished PCBs undergo a final inspection to ensure that they meet the customer's specifications and are free from defects.

- Testing: PCBway conducts various tests to ensure the functionality and reliability of its PCBs. They use advanced testing equipment and techniques to test PCBs for continuity, insulation resistance, and other critical parameters.

- Certification: PCBway is certified to various quality management standards, including ISO 9001:2015, UL, and RoHS. These certifications ensure that their PCBs meet the highest quality standards and comply with regulatory requirements.

- By implementing a rigorous quality control system, PCBway can ensure that their PCBs are of the highest quality and meet the needs of their customers.

In conclusion, PCBway plays a crucial role in supporting innovation and growth in the electronics industry. Their wide range of PCB capabilities, commitment to sustainability, quality assurance, and exceptional customer service have made them a trusted partner for companies across various industries. PCBway's dedication to providing reliable and efficient PCB solutions has helped its customers bring their ideas to life and stay ahead of their competition. If you're looking for a reliable PCB manufacturer, look no further than PCBway.