When it comes to the design process, engineers don’t just have a lot to think about; they also have a lot of constraints. Time, money, and resources are all limited. When it comes to designing a new PCB and purchasing the components needed for that PCB, your budget is probably one of your most restricting factors. But how can you get the best value out of your budget? Thankfully, there are ways to get the most bang for your buck (without sacrificing quality). In this blog post, we’ll take a look at some of the benefits of using PCBWay as your primary vendor for printed circuit boards (PCBs) and component procurement.

PCBWays PCB & Component Cost Estimator

Another great feature of PCBWay is its cost estimator tool. When customers order a PCB design from PCBWay, they can use the cost estimator tool to estimate the final price of the board. Customers can select board dimensions, components, and options to get a cost estimate. The estimator will estimate the cost of purchasing the board materials and printing the board design, and the price will be broken down by the components used on the board. This is a great way to get a general idea of how much a PCB will cost, and can help customers determine if their budget is allowing them to purchase what they need on the board.

PCB Manufacturing with SMT Components

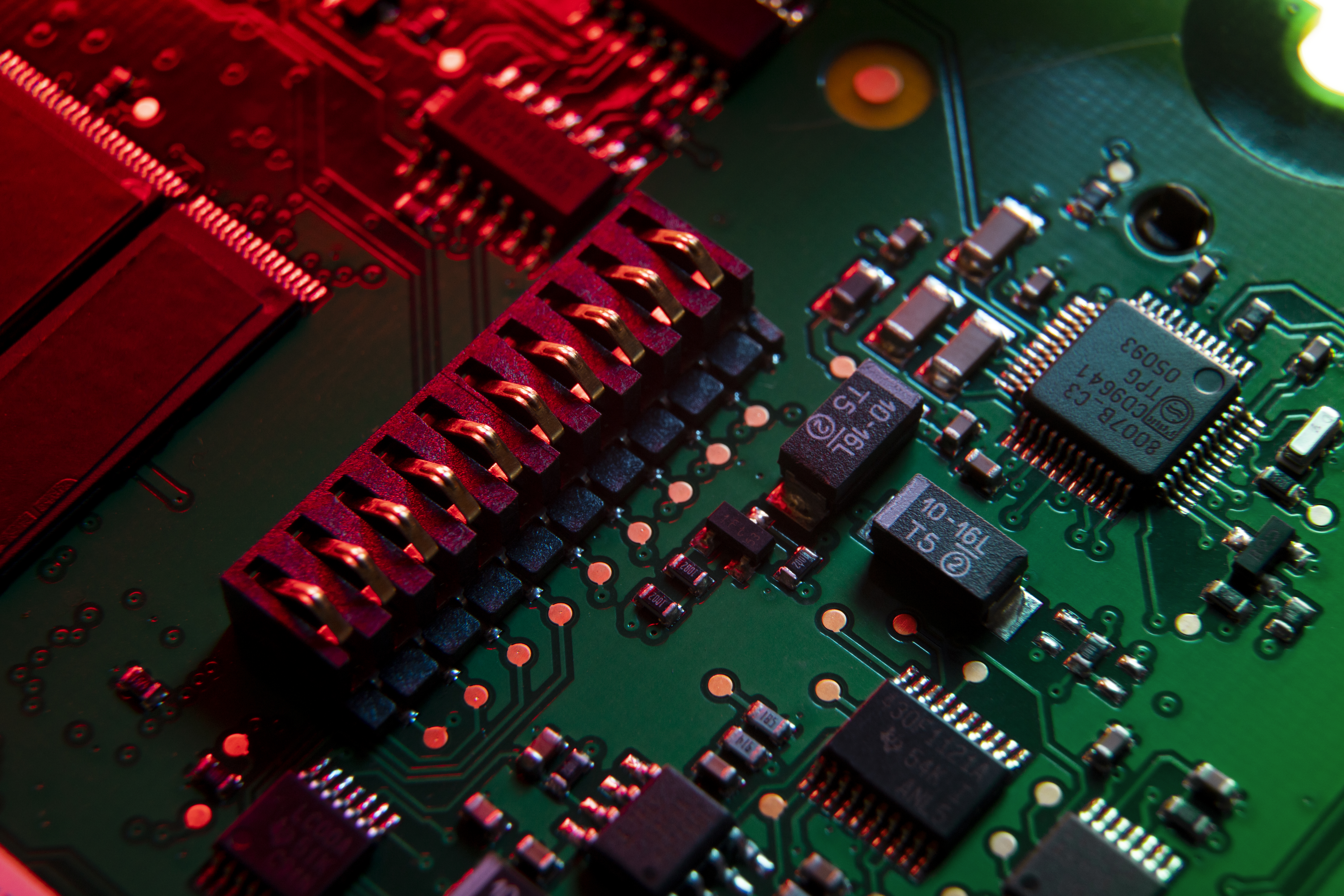

At the heart of PCBWay’s business model is the printing of PCBs. PCBWay’s manufacturing facilities are equipped with a variety of high-quality printing equipment that enables them to print PCBs with a range of components. PCBWay’s manufacturing facilities are located in Asia and are compliant with global manufacturing standards. Each PCBWay manufacturing facility is capable of producing up to 5,000 boards per day.

PCBWay’s production process for PCBs with SMT components is explained below: First, the manufacturing requirements for the PCB are loaded into the system. This includes designs, component requirements, board dimensions, and other specifications. Once the requirements are loaded, the manufacturing engineers begin designing the board. This board design can either be designed internally or outsourced. For large PCBs, PCBWay uses an in-house design team that can design PCBs in a variety of different design styles. For smaller PCBs, PCBWay uses an external design team that can design PCBs in a variety of different design styles.

Once the PCB design is finished, the design is sent to a PCB manufacturer for production. Depending on the PCB type, PCB manufacturers may be located in-house or off-shore. Once the design is approved, the PCB is manufactured. The manufactured PCB is then inspected for quality control. Finally, the PCB is packaged and shipped to the customer.

Some Final Words on PCB Manufacturing Costs

We've focused on the costs associated with PCB design and selection, but there are other factors that can affect the overall cost of manufacturing a PCB. These factors include the capabilities of your PCBWay logistics provider, the availability of your preferred materials, the quantity and type of inspection required for your products, and the PCBWay printing process. In addition, the PCBWay platform offers a variety of tools that can help reduce the cost of your PCB production, including discount codes, volume-based discounts, and special offers. Whether you’re designing a small or large PCB, these tools can help reduce the cost of your PCB production.

It’s Cheaper to Outsource Your PCB Prototyping to PCBWay

The first and foremost reason to outsource your PCB prototyping services to PCBWay is that it is cheaper. China has been the hub of manufacturing for decades now, and its economy is heavily reliant on this business. This has resulted in the cost of production going down significantly, making it cheaper to manufacture products in China than in other parts of the world. So if you decide to outsource your PCB prototyping to China, you will most likely be getting your PCBs at a significantly lower price than you would if you outsourced PCB prototyping services to any other country.

Summary

With the right tools and a little bit of creativity, even a small PCB can be designed and manufactured at a reasonable cost. To get the best value out of your budget, it’s important to know how much your project will cost upfront. To estimate the cost of your project, you can use a cost estimator, review the prices of your components, and know exactly what your materials need to cost. Once you have a good idea of your project costs, you can use these tips to get the best value out of your budget.