It's critical to engage with an assembler that can turn your ideas over quickly if you require prototype printed circuit boards. These boards assist in ensuring that you have the correct design before beginning a complete production run, allowing you to prevent costly mistakes. The sooner you receive your prototype circuit board, the sooner you can test it and begin manufacturing on your standard run. PCBWay is a PCB maker that responds quickly. PCBWay provides quick-turn PCB prototypes to help you get your prototype boards out quickly while still adhering to your design criteria.

Printed Circuit Board Prototypes Meet High-Quality Standards

PCBWay provides speedy PCB prototype services for high-quality, low-cost PCBs. We follow quality management systems to the letter, and we have an in-house quality control department that ensures that every work complies with high standards.

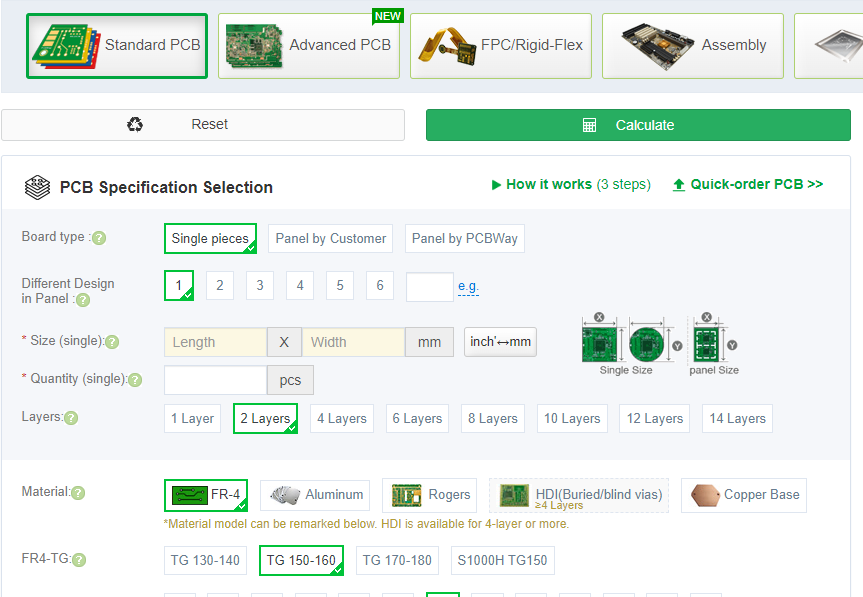

We can prototype your PCB in 3-7 days, depending on your specific needs, compared to 6-18 days for Standard PCB service. In the table below, you can see our circuit board prototype capabilities:

Standard PCB Service vs. Prototype PCB Service

When you need a PCB prototype, use the PCB Prototype service.

- Boards for design review or quality assurance testing prior to manufacturing

Our PCB prototype service is an excellent approach to ensure that your design is free of flaws before going into mass production.

- PCB Turnaround in a Hurry

Rapid PCB prototyping ensures that you receive your boards quickly.

- Boards with less than eight layers

We provide rapid PCB prototyping for boards with no more than eight layers because we want to get your boards back to you as soon as possible.

- FR-4 Board

Standard FR-4 material will be used for your printed circuit board prototype.

- IPC1 Boards of High Quality

If you want the following services, please choose the Standard PCB service:

- Full Production Boards

You can contact us for standard PCB service for complete manufacture for usage in your applications once you've confirmed that your design works.

- Turnaround Time Is Slightly Longer

It takes a bit longer to make sure we have everything just perfect because these are the boards you'll be utilizing. However, now that you've tested the concept, you may start working on your projects as soon as your boards arrive.

- Up to 9-32 Layered Boards

Once we have the time to build your whole board, we will have a lot more versatility with materials and layers.

- Boards made of FR-4, aluminum, flex, or other unusual materials

- IPC2 Boards of High Quality

What Are the Advantages of Using a Prototyping Circuit Board?

- Quickly test and correct designs if they are incorrect.

- Detect any design flaws early in the development of your projects.

- If required, order low-quantity production runs with a MOQ of only five boards.

- Take advantage of lower manufacturing tolerances.